A Behind-the-Scenes Look at Our Signage Production Workflow

Most signage providers outsource key steps, risking delays and inconsistent quality. At Midland Signs, every stage of our signage production happens under one roof, giving you full control and unmatched precision. In this post, you’ll see how our blend of advanced CNC machines and expert craftsmanship delivers bespoke signage tailored exactly to your needs. For more insights into the process, visit The Signage Production Process: From Concept to Installation.

Understanding Our Signage Production

Discover the meticulous process behind our signage production, where every detail counts.

Overview of the Workflow

At Midland Signs, we take pride in handling everything in-house. This means your signs are crafted with precision, right from the initial design to the final touches. You might wonder why this matters. When we manage the entire process, you get the benefit of consistent quality and faster turnaround. There’s no waiting for a third party to do the job. Each stage, whether it’s cutting, bending, or finishing, is done with your needs in mind. You have the assurance that your project is our focus from start to finish.

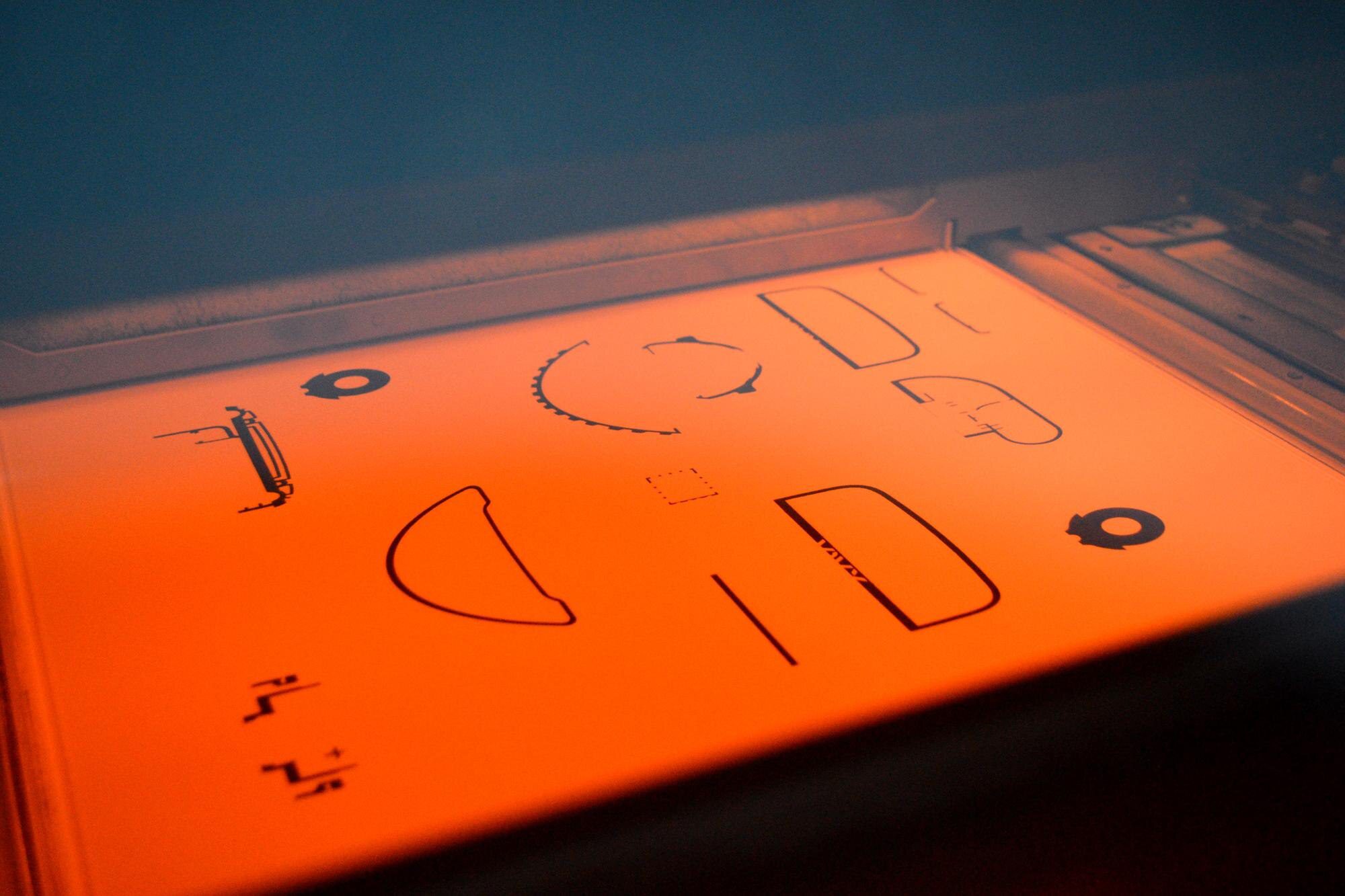

The Role of CNC Machines

CNC machines play a crucial role in our workflow. These cutting-edge machines allow us to achieve precision that simply isn’t possible by hand. Imagine a craftsman, but one that never tires and can repeat the exact same task perfectly. That’s what CNC technology offers us. They cut materials with an accuracy of 0.001 inches, ensuring every sign is identical to the design you approved. This means your signage will not only look great but also fit perfectly wherever it’s installed. By using CNC machines, we’re able to maintain high standards without compromise.

Ensuring Quality Control

Quality is at the heart of what we do. Each sign undergoes rigorous checks to ensure it meets our high standards. From the start, we implement measures to catch any discrepancies early. Our team inspects every piece for colour accuracy, material integrity, and structural soundness. You’re not just getting a sign; you’re getting a promise. This is why so many businesses trust us to deliver signage that not only meets but exceeds their expectations. Our commitment to quality is unwavering.

Crafting Bespoke Signage

Explore how we create custom solutions tailored to your unique needs and preferences.

Tailoring to Client Needs

At Midland Signs, we believe every business is unique, and so should its signage be. We start by understanding your vision and requirements. Whether it’s a storefront sign or event signage, our team listens to your ideas and provides expert advice. You might think all signs are the same, but personalization makes a significant difference. It’s not just about aesthetics; it’s about brand representation. By tailoring each project, we ensure your signs are a true reflection of your business identity.

Traditional Craftsmanship Techniques

While technology is essential, we haven’t forgotten our roots. We blend modern techniques with traditional craftsmanship to deliver exceptional results. Our skilled artisans bring decades of expertise to each project. They apply hands-on techniques that machines can’t replicate. This combination ensures your signage has a unique touch that’s both modern and timeless. You gain the advantage of tradition and innovation working hand in hand, creating a product that’s both durable and visually appealing.

Benefits of In-house Manufacturing

Handling production in-house offers numerous advantages. It gives us control over every aspect of the process, ensuring consistency and reliability. You get faster turnaround times because there’s no need to wait for external suppliers. This means if you have a tight deadline, we can accommodate it. Plus, by keeping everything under one roof, we reduce costs, allowing us to offer competitive pricing without compromising on quality. In-house manufacturing is a win-win for both us and our clients.

Advanced Technology in Production

Discover how our cutting-edge technology ensures unparalleled precision and quality in every sign we produce.

Precision Craftsmanship with CNC

Precision is vital in signage production, and our CNC machines deliver this consistently. They allow us to cut, shape, and engrave with unmatched accuracy. Think of them as the ultimate tool for precision craftsmanship. With control down to the millimetre, we can produce intricate designs that stand out. This technology not only enhances the aesthetic appeal of your signs but also ensures they perform as needed. Your signs will attract attention for all the right reasons.

Enhancing Quality Control Measures

Our commitment to quality involves continuous improvement. We regularly update our processes to incorporate the latest in quality control technology. Every sign is checked multiple times during production to ensure it meets our stringent standards. This dedication means you can trust that your signage will withstand both time and the elements. By constantly refining our approach, we remain at the forefront of the industry, ensuring our clients receive the best.

The Future of Signage Solutions

The future of signage is bright, with technology opening new possibilities. At Midland Signs, we’re excited about the potential innovations in sign-making. From smart signs that interact with customers to eco-friendly materials, we’re exploring every avenue. By staying ahead of trends, we ensure our clients have access to the latest and best. The longer you wait to embrace these innovations, the more you’ll miss out on opportunities to enhance your brand presence. Stay ahead with Midland Signs.

In summary, our comprehensive in-house production ensures you receive high-quality, bespoke signage tailored to your exact needs. With a blend of traditional craftsmanship and cutting-edge technology, Midland Signs is your trusted partner in creating impactful signage solutions.